PROJECTS

Specialising in custom built coating solutions

Technosol has the capability for a wide range of projects. Technosol has collaborated with a number of contractors over the years to deliver high quality specialist floor finishes and large-scale projects.

Read about some of our successful completions below:

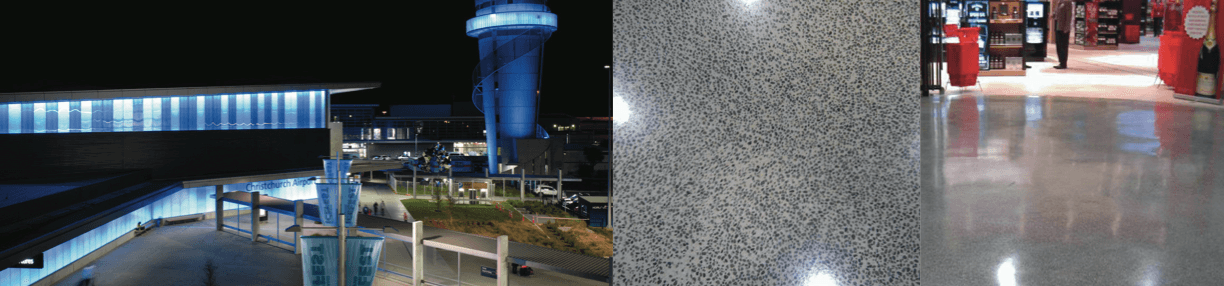

Christchurch International Airport

Architectural Terrazzite Flooring

Technosol, as a sub-contractor to Hawkins for the construction of the Christchurch Airport International Terminal, was responsible for the installation of the Architectural Terrazzite Floor in the International Departure Lounge.

Architectural Terrazzite from Nuplex, is a resin-based terrazzo flooring product, designed to recreate the radiance and shine of polished marble floors. A synthetic, monolithic floor topping, it combines a wide spectrum of design features and colour options with long term durability for floors subject to high levels of pedestrian traffic, and therefore was an excellent finish choice for the International Airport flooring.

The system is a blend of coloured polyester resin, coloured marble aggregates and fillers which are trowelled over concrete, tile or terrazzo surfaces.

Technosol has been an approved Nuplex applicator since the company was first established over 20 years ago.

Technosol is justifiably proud of the Architectural Terrazzite Floor. It is still as pristine today as it was when it was first laid.

Pioneer Pool Christchurch

Installation of Resin based floor topping with Technosol Grit

Pioneer Pool is a community centre with several covered pools. Christchurch City Council identified a slip issue on tile surfaces around the Learn to Swim Pool and adjoining change facilities.

A pool refurbishment project required all existing floor tiles to be removed, floor surfaces diamond ground and new non-slip resin and Technosol grit topping installed. New pool edge tiles were laid and expansion joint sealant removed and replaced.

This project was completed during the school holidays, without disruption and on time.

The Court Theatre

Brick Wall Strengthening and Floor Remediation

Cracks to concrete walls and to 30 of the 44 concrete interior columns required remediation using our injection process for cracks up to 2.0mm in width, and our structural grouting process where damaged areas were larger.

Brick walls required structural strengthening using FRP (Fibre Reinforcing Polymer) methods. In addition, joint sealant works were undertaken between block walls and columns.

As an authorised applicator for Mapei and Sika, Technosol liaises closely with the suppliers and the project engineers to ensure that methodologies employed are effective for the purpose.

The concrete floor in the entrance access, toilet lobby, and fire exits were prepared and ground to receive applications of Nuplex Crystal Sealer. The polished concrete floor fits perfectly with the ambience of the building and keeps it true to the architect’s designs and ideas that it is “rough and ready but, in a city recovering from an earthquake, it is all you need.”

Nuplex Crystal Seal is a clear, solvent based polymer supplied in a thin, ready to use form to ensure good penetration into the substrate. Crystal Seal possess excellent durability, toughness, water resistance and is non-yellowing.

Christ’s College - School House

Brick Wall Strengthening

The Christ’s College School House was constructed in 1902 and opened as a boarding house in 1909. The building has a category II heritage listing with the New Zealand Historic Places Trust and a Group 3 listing in the Christchurch City Plan. School House comprises three levels of timber floors, supported on unreinforced masonry walls.

A number of repairs were required to bring the building back to a pre earthquake capacity, one of which was the replacement of strength lost due to cracking of north wall with FRP strengthening.

Glass Fibre Reinforced Polymer (FRP) was installed to the internal face of the unreinforced masonry walls, primarily to provide shear strengthening of the masonry walls. Vertical FRP strengthening was also required to prevent rocking of the piers in isolated locations.

Following completion of the strengthening works the northern wall achieved the following capacities under in-plane loads: Second floor 100%; First floor 85%; and Ground floor 65%.

LET'S CHAT

Get in touch with the coating solution specialists today to get started on your project.

Email us: technosol@technosol.co.nz →

Call us: 03 338 3663 →